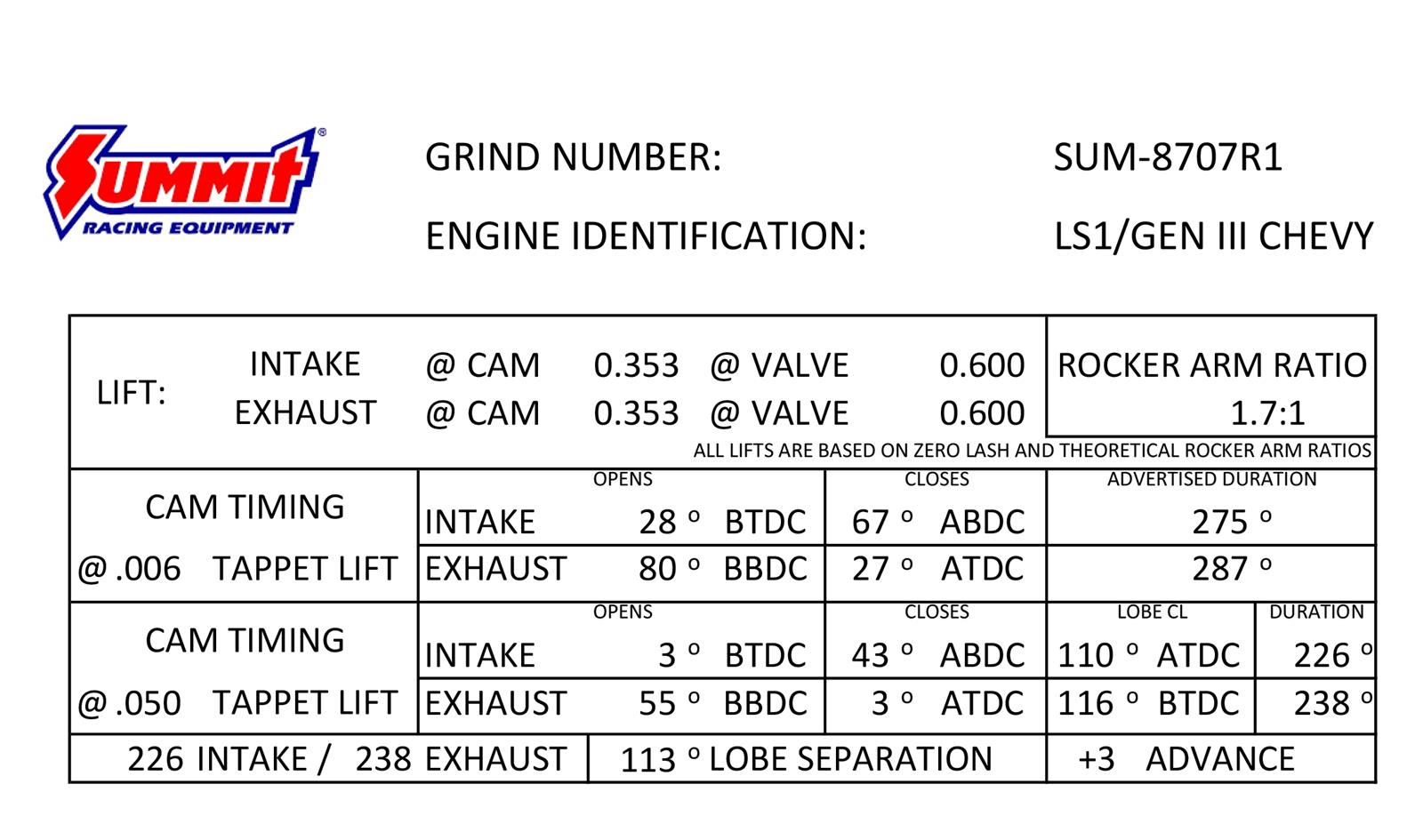

Summit Racing™ Pro LS Automotive Camshafts SUM-8707R1

- Find Summit Racing™ Pro LS Automotive Camshafts For Sale. Stage 2 Pro LS Cam. 226/238 113+3

- .600/.600 Lift

- 3-bolt

- 4.8

- 5.3

- 5.7

- 6.0

- 6.2

- 7.0

- Vortec Truck LS1 LS2 LS6 LS3 LS7 LSA LQ4 LQ9 LS9 LS4 LY6

Manufacturer’s Part Number: SUM-8707R1

Summit Racing Part Number: SUM-8707R1

UPC: 190861251441

Cam Style: Hydraulic roller, OE roller

Camshaft Use: Racing

Camshaft Manufacturers Description: Not intended for use with VVT or AFM. The Summit Stage 2 LS cam is the biggest cam for a daily driver. It has a steady lope and tunes well with a minimum of hassle. It uses state-of-the-art cam lobe designs to pull strongly to 7000 rpm with as little as 150 lbs. of seat pressure.

Basic Operating RPM Range: 3,000-7,000

Intake Duration at 050 inch Lift: 226

Exhaust Duration at 050 inch Lift: 238

Duration at 050 inch Lift: 226 int./238 exh.

Advertised Intake Duration: 275

Advertised Exhaust Duration: 287

Advertised Duration: 275 int./287 exh.

Intake Valve Lift with Factory Rocker Arm Ratio: 0.600 in.

Exhaust Valve Lift with Factory Rocker Arm Ratio: 0.600 in.

Valve Lift with Factory Rocker Arm Ratio: 0.600 int./0 600 exh.

Lobe Separation (degrees): 113

Camshaft Gear Attachment: 3-bolt

Remanufactured: No

Computer-Controlled Compatible: Yes

Valve Springs Required: Yes

Quantity: Sold individually.

Notes: Not intended for use with VVT or AFM. The Summit Stage 2 LS cam is the biggest cam for a daily driver. It has a steady lope and tunes well with a minimum of hassle. It uses state-of-the-art cam lobe designs to pull strongly to 7000 rpm with as little as 150 lbs. of seat pressure. Camshaft features base circle of 0.720 int./0.720 exh.

Summit Racing™ Pro LS Automotive Camshafts ( Find Summit Racing™ Pro LS Automotive Camshafts For Sale )

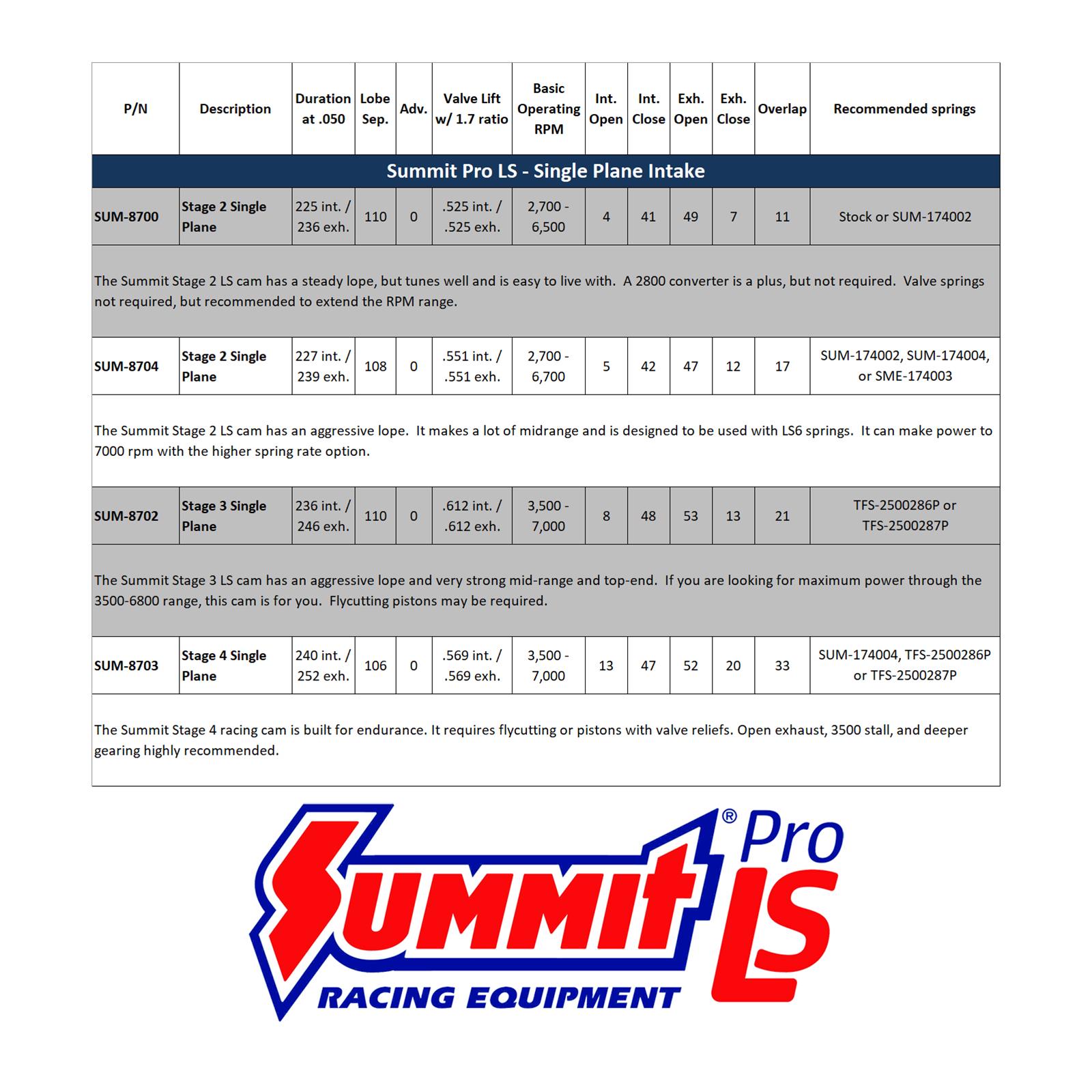

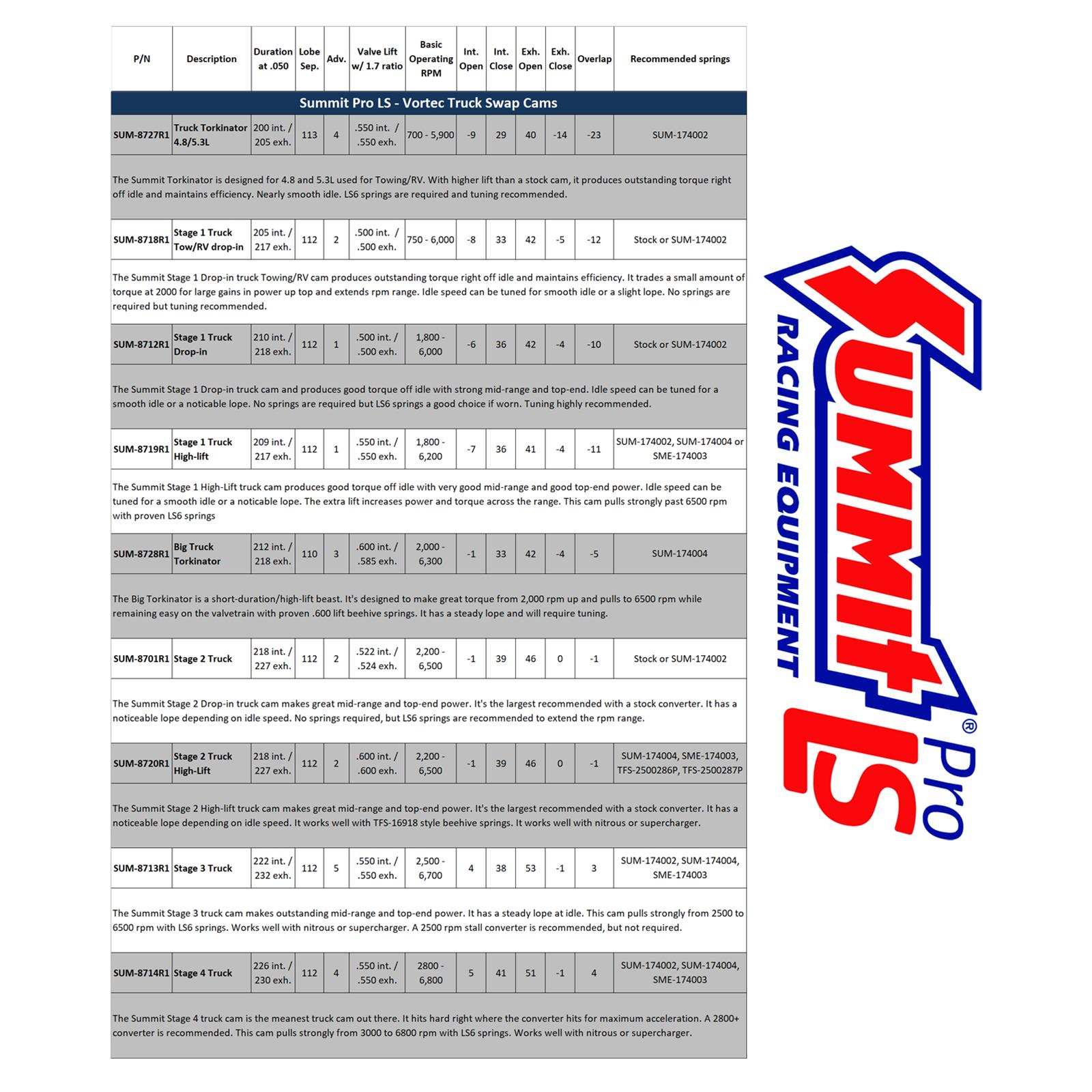

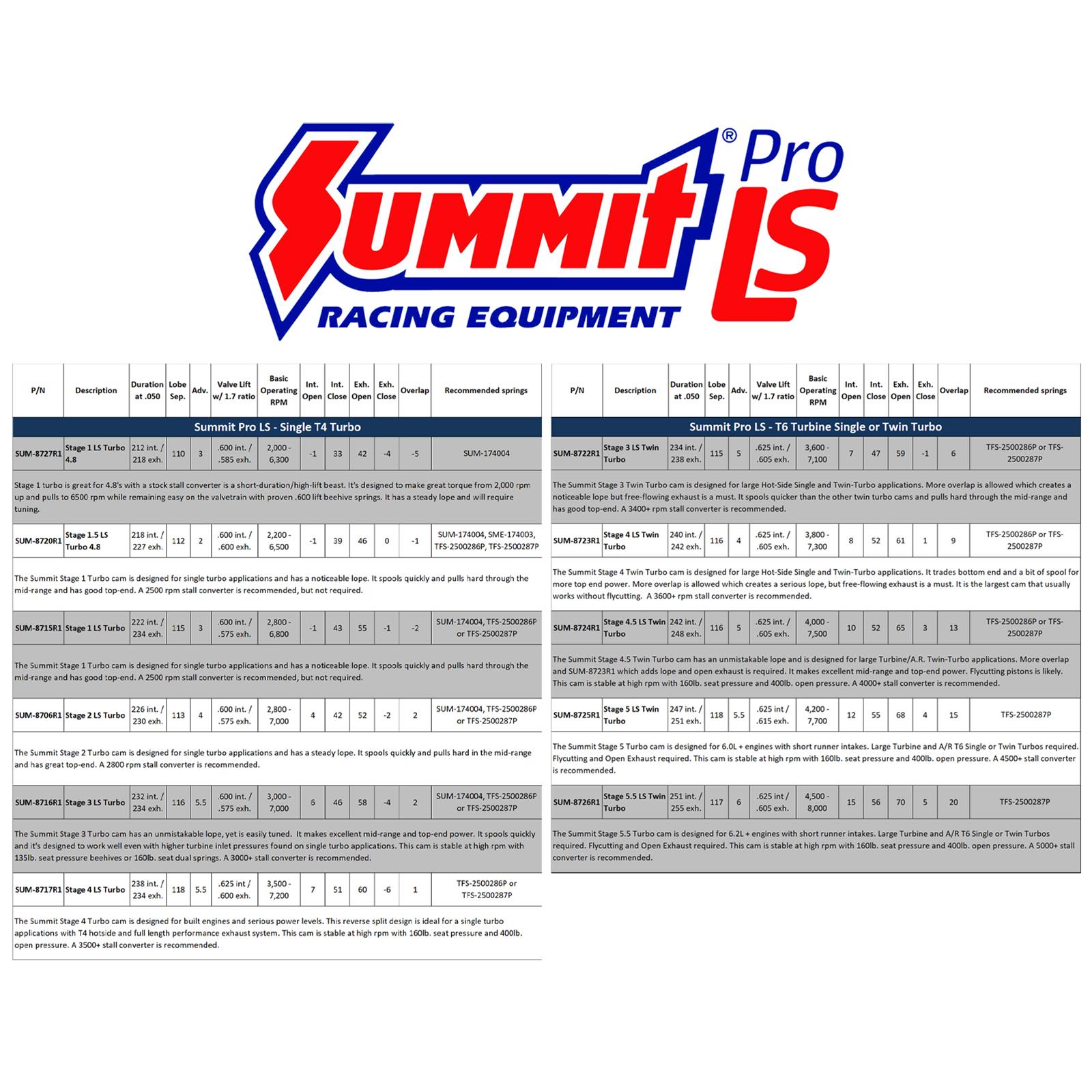

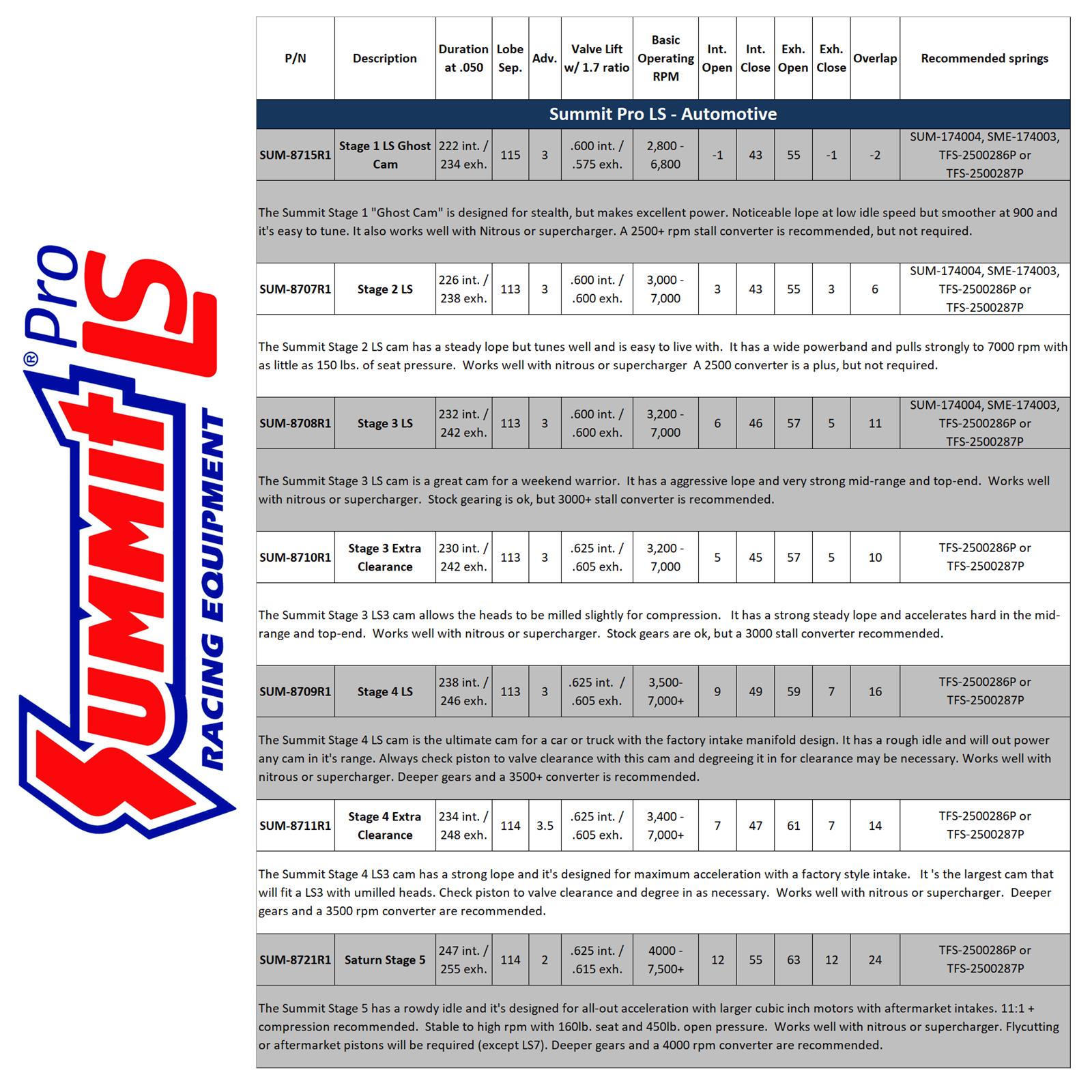

Summit Racing™ Pro LS Automotive cams are affordable and designed in stages with very specific cam timing for each individual application in cathedral and rectangle port versions. This ensures maximum performance and gives you the idle you are looking for. The lobes are designed for stability at high rpm with the spring pressures found in quality .600 and .670 in. spring packs. Careful design guarantees the cams can be installed with minimal difficulty. Although piston to valve clearance should always be verified, the Stage 2 and 3 cams often allow for additional cylinder head milling. The Stage 4 cams often require no changes but can be degreed slightly different as needed. Starting with American bearing steel, they are precision machined on a Landis 3LB CNC grinder with CBN diamond wheels for unmatched quality.

Reviews

There are no reviews yet.